MOBIL STERILIZATION SYSTEMS

Vertisa Mobile Medical Waste Sterilization Solutions for Medical Waste Treatment and Disposal

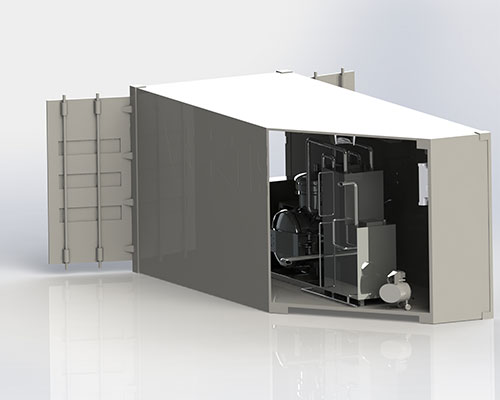

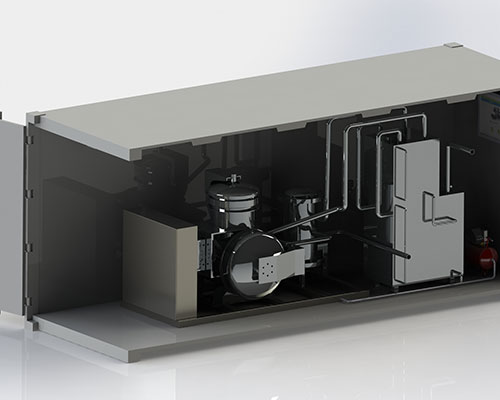

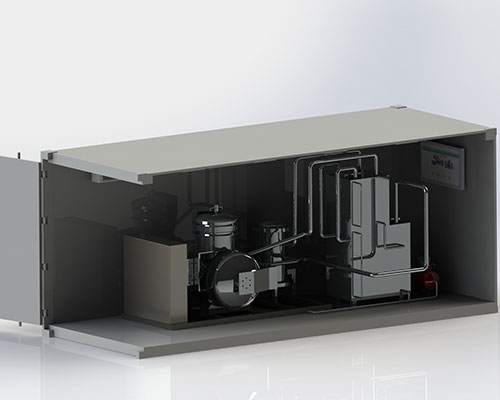

Mobile Medical Waste Treatment Unit, caters to many other customized demands, such as in stand alone wate steriilization facilities, military field hospital, emergency situations such as nature disaster and epidemic diseases, or taking care of marine and island’s medical waste.

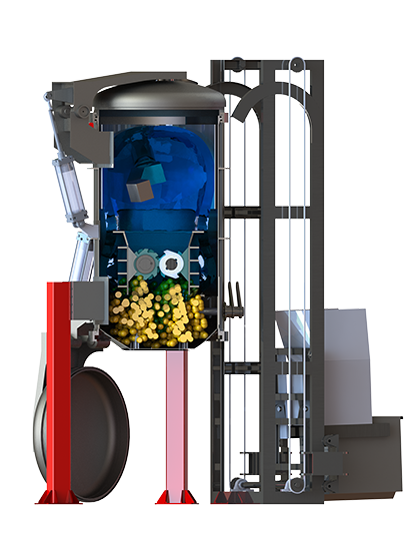

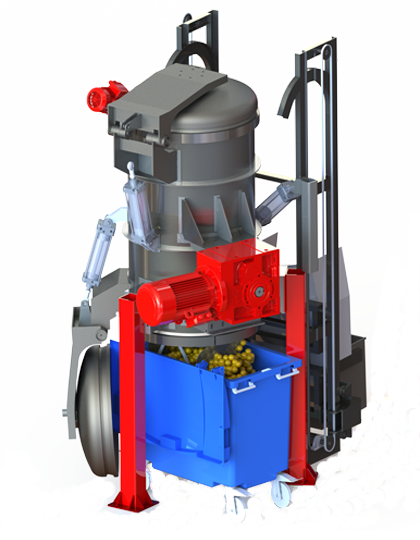

The system is composed of autoclavewith integrared shredder, boiler and if requeted dedicated power generator. It works 24/7 as long as water and diesel available.

STERİLİZASYON SÜRECİ

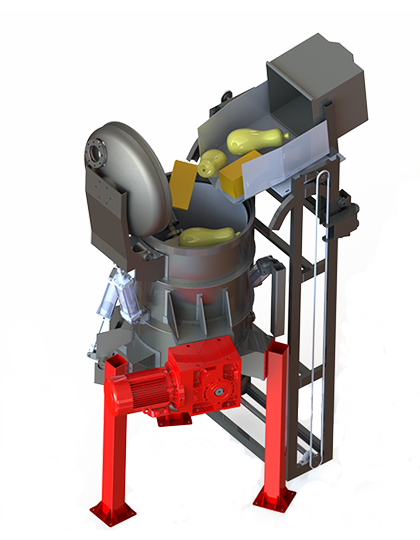

LoadingShreddingHeating / SterilizationCooling and DrainingUnloading

|

At the begining of the cycle , once the upper lid opens, the automatic elevator empties the waste in the loading chamber. As the upper lid closes shredding starts. |

GENEL ÖZELLİKLER

| Technical Features | Value |

| Size (L x W x H) (mm) | 2200 x 1500 x 1500 |

| Weight (Kg) | 1850 |

| Air Pressure (Bar max) | 8 |

| Electrical connection required (Kw) | 17* |

| Working Characteristics | Value |

| Sterilizing Capacity (Kg/ Hour) | 150 |

| Process Volume Capacity (Lt.) | 870** |

| Average Waste Density (Kg/m3) | 100-150 |

| Average Cycle Time (Min.) | 30 |

| Maximum Steam Flow (Kg/Hour) | 290 |

| Sterilization Efficiency (SAL) | 8 Log10 |

| Consumption / Cycle | Value |

| Steam (Kg) | 13 |

| Electricity (Kw) | 4** |

| Water (Lt) | None*** |

| Special Consumables | Autoclave Bags |

* P50 – P100 – P150 includes built in electrical steam boiler

** Electrical consumption of the sterilzer only

*** Water consumption of integrated steam boiler: 7 – 12 Lt./ Cycle