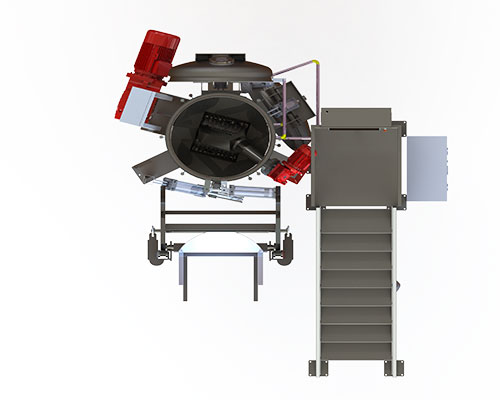

PROMED P300

Capacity: 100 Kg/H (220 Lbs/H)

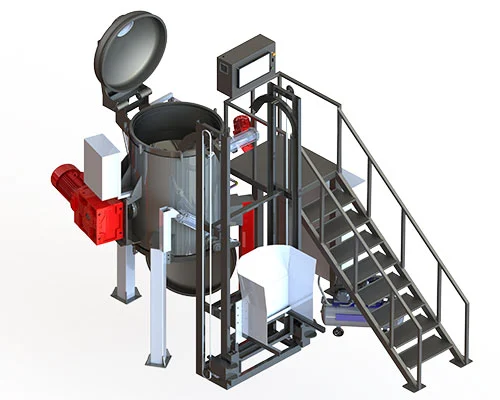

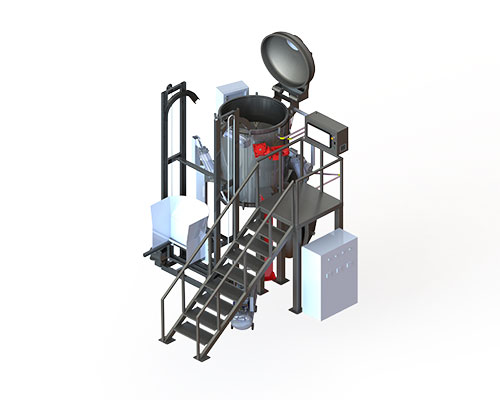

Field of Utilization: Large size hospitals and industrial sterilization facilities

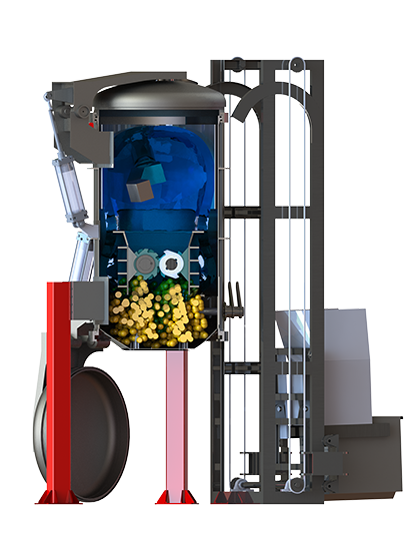

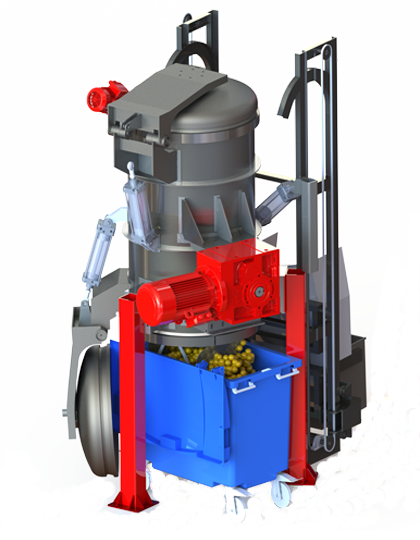

- Pressure container built of high quality Stainless Steel

- Design and production certified by TUV Austria

- Produced according to EU Directives PED (2014/68/EU) 2006/42/EC, 2014/30/EU & EU Norms EN285

- Sophisticated automation control system with advanced reporting and monitoring software

- Online access via internet for supervision and troubleshooting

- Fully automatic operation- no need for any operator intervention

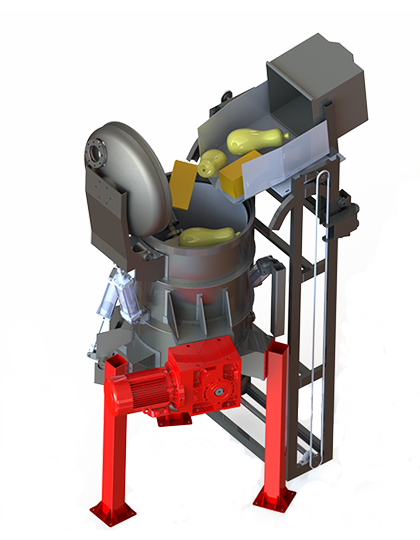

- Automatic elevator system for easy loading

- No water consumption

- Low fuel and electrical consumption for integrated steam boilers equipped with state of the art steam regeneration system

STERILIZATION PROCESS

LoadingShreddingHeating / SterilizationCooling and DrainingUnloading

|

At the beginning of the cycle , once the upper lid opens, the automatic elevator empties the waste in the loading chamber. As the upper lid closes shredding starts. |

GENERAL FEATURES

| Technical Features | Value |

|---|---|

| Size (L x W x H) (mm) | 2000 x 2000 x 3600 |

| Weight (Kg) | 2200 (Sterilizer only) |

| Air Pressure (Bar max) | 8 |

| Electrical connection required (Kw) | 15 |

| Working Characteristics | Value |

| Sterilizing Capacity (Kg/ Hour) | 80-100 |

| Process Volume Capacity (Lt.) | 400-450 |

| Average Waste Density (Kg/m3) | 100-150 |

| Average Cycle Time (Min.) | 30-40 |

| Maximum Steam Flow (Kg/Hour) | 270 |

| Sterilization Efficiency (SAL) | 8Log10 |

| Consumption / Cycle | Value |

| Steam (Kg) | 11 |

| Electricity (Kw) * | 4 |

| Water (Lt) | None |

| Special Consumables | None |

* Electrical consumption of the sterilizer only